Keeping with the Stohr design ethos

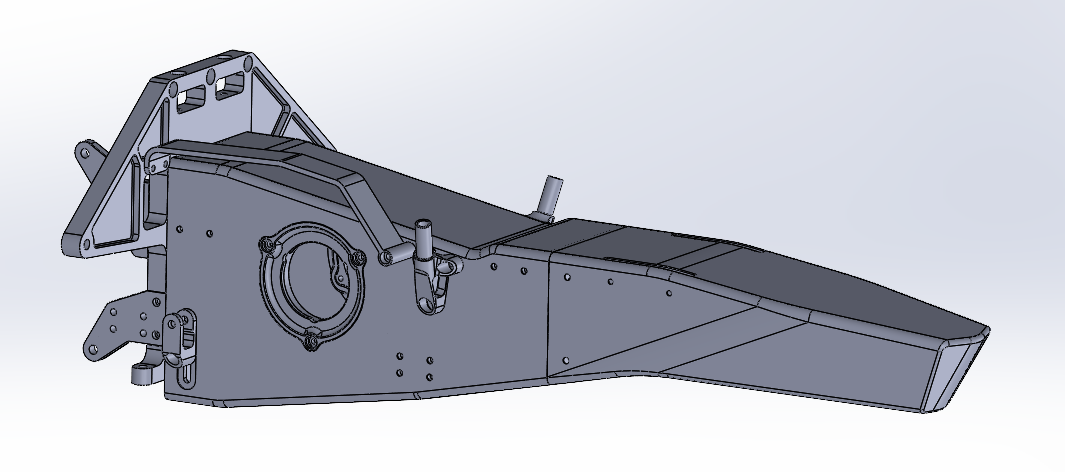

It's been a few weeks since we announced a changing of the guard here at Stohr Racing Cars, and a week since our inaugural quarterly webinar. We talked about the current market environment Stohr operates in, and what we're doing to re-stohr our production capabilities. In that conversation, we also let a couple of new cats out of the bag: the coming carbon spar, and of course the RC1.

When it came to developing new parts, folks had quite a few questions about how we were thinking about backward compatibility with their current cars, and what approach we would take to address the desire to improve the WF1 without changing, well, everything! So I figured it'd be valuable to zoom into what we value when developing and designing new parts, in the context of the new carbon spar.

Simplify, then add lightness

The great Colin Chapman once said of his race car design philosophy, "simplify, then add lightness" - a guiding principle since the early days of Stohr Cars. The WF1 and 01d before it exemplify this philosophy, and it continues to guide us in our design exploration as we think about new parts, and new cars. Do the same job with fewer parts, manufacture them with fewer operations, and simplify the preparation and steps for each operation. If our approach doesn't simplify the car, or add lightness, we should probably rethink it. Innovation and finding simple, clever solutions to the complex dynamic challenges one finds in racing are what keep us coming back again and again.

The carbon spar is a natural technological successor to the current aluminum spar, allowing us to radically simplify a structurally significant area of the car, while adding lightness in a desirable area at the tail end of the car.

Designing for purpose

If the new part doesn't achieve a specific goal, if it doesn't advance the status quo in some way, then it probably doesn't need to be designed and manufactured. We are not believers in redesigning things just to force customers to buy more product from Stohr. Every aspect of what I develop for Stohr entails answering the root question of what it achieves for the customer. In the case of the carbon spar, that purpose has several facets:

- improve handling responsiveness and consistency

- allow 1:1 motion ratio use for large spring diameters

- future-proof engine installations

- provide a built-in oil sump for dry-sump engines

- reduce chain alignment and tensioning complexity

- improve impact attenuation at the rear of the car

Minimizing arbitrary change

Major design features tend to have interfaces and boundaries that help us keep control of design creep, preventing one car from creeping wholesale into another. Changing one part on a car ideally should not have the knock-on effect of forcing the rest of the car to be updated at the same time. Sometimes these effects are unavoidable - the change from the 01d engine bay to the WF1 engine bay, for example. The cost of making material improvements to the stiffness of the engine bay meant an entirely new interface with the WF1 trunnion arms and "elephant ears".

In that spirit, the carbon spar will be a bolt-in replacement for your aluminum spar, even allowing reuse of your existing suspension parts from the a-arms out to the uprights.

Leaning into our strengths

Every organization has core strengths, and Stohr is no different. One of ours is composite engineering and manufacturing. As I mentioned in the inaugural webinar, other manufacturing areas such as machining and fabrication are works in progress that I expect to be reporting steady improvements on in the coming months. But composite structures have long been a preferred technology approach going back to our fledgling days as Dauntless Racing where we started off making carbon fiber aero bits for our Ralt RT-41 Formula Atlantic car.

Leveraging carbon composite structures in the new spar facilitates radical simplification of design, achieves significant reduction in parts count, and adds lightness without sacrificing safety or cost.

See y'all at the pointy end of the grid!

Rennie